Yazar: ZTF Jeotermal Boru

Benefits and Areas of Use of Heat Insulated Pipes

Like a blanket, heat insulated pipes protect a plant from cold and heat loss, the effect of energy efficiency on it lays the foundation.

In greenhouses or thermal facilities where climate control is mandatory, the quality of insulation directly affects both comfort and productivity.

By using insulated pipes, it is possible to reduce heat loss and optimize energy consumption, which means significant cost savings in the long run.

İçindekiler

- 1 The Role of Heat Insulated Pipes in Energy Efficiency

- 2 Selection Criteria for Heat Insulated Pipes

- 3 Cost Analysis and Savings Potential

- 4 Application Areas of Heat Insulated Pipes

- 5 Frequently Asked Questions About Heat Insulated Pipes

- 5.1 Do heat insulated pipes provide energy efficiency?

- 5.2 What are the environmental benefits of heat insulated pipes?

- 5.3 Is the initial cost of heat insulated pipes high?

- 5.4 What materials are used in the production of heat insulated pipes?

- 5.5 Is it difficult to install and maintain heat insulated pipes?

- 5.6 Where are heat insulated pipes used?

The Role of Heat Insulated Pipes in Energy Efficiency

Heat insulated pipes its use has become a critical element of the efficient use of geothermal energy resources. These pipes allow hot water or steam extracted from underground to be transferred without any loss of energy on its journey to the points of use on the surface. In particular, the use of insulated pipes in greenhouse heating systems or thermal hotel investments has a fundamental role in maintaining the maximum level of energy required to meet the need for thermal energy.

Well insulated pipes offer both environmental and economic benefits by increasing the overall energy efficiency of the system. Thanks to these pipes, which minimize energy losses, while reducing the carbon footprint, operating costs are also reduced. Therefore, the selection of pipes that meet high thermal efficiency standards stands out as an integral element in sustainable energy use and cost management.

Reducing Heat Loss

Thermally insulated pipes are a key factor in the effective use of geothermal energy—they are designed to minimize heat loss.

The use of heat insulated pipes can prevent heat loss between 40-60%, providing significant savings in energy costs.

At the point of increasing energy efficiency, the quality of the insulation material and the installation of the pipes are of great importance; the right preferences provide significant benefits in the long term.

Minimizing heat loss, in addition to reducing carbon emissions, also leads to a decrease in total energy consumption, which means a reduction in costs and environmental impacts.

Saving Energy in the Long Run

The use of heat-insulated pipes is one of the main elements of a sustainable energy management strategy. These pipes, which are of great importance especially in the efficient use of renewable energy sources such as geothermal energy, contribute to reducing costs in the long term.

- Reduction of Energy Losses: Heat insulated pipes maximize efficiency by minimizing energy losses.

- Reduction of Operational Costs: Thanks to thermal insulation, the amount of energy required by the systems is reduced, which leads to a decrease in operational costs.

- Reduction of Maintenance Expenses: Low heat loss reduces the overall wear and tear of the pipe system, reducing maintenance costs.

- Prolongation of Equipment Life: Thanks to the thermal insulation, the operation of the system components under low stress extends the life of the equipment.

- Reduction of the Impact on the Environment: Along with the reduction of energy consumption, the carbon footprint and environmental impacts are also reduced to a minimum.

The costs of insulated pipes, which initially seemed to be high for investors, are actually energy saving thanks to it, he is able to pay for himself in a short time.

Success in the installation of heat insulated pipe systems is ensured by the correct product selection and high quality installation applications. Thus, the system works at full capacity efficiency, significantly reducing total ownership costs.

Minimizing Environmental Impacts

Heat insulated pipes reduce the use of natural resources.

These pipes play a critical role in significantly reducing greenhouse gas emissions. Thanks to high energy efficiency, fossil fuel consumption decreases, which contributes to the reduction of carbon emissions. Because when the heat loss is reduced to a minimum, the amount of energy required for heating and cooling decreases significantly.

As energy consumption decreases, environmental damage decreases.

They offer a one to one solution for the protection of energy resources. Improving energy efficiency is directly linked to environmental protection activities, which means that we use less fossil fuels for our heating and cooling needs – this alleviates the environmental burden created by fossil fuels.

This is an important step in the fight against climate change. In the long term, the widespread use of heat insulated pipes helps to reduce the global carbon footprint, while encouraging an industrial approach focused on energy efficiency. in order to achieve the goals we have set for energy consumption in 2024, such innovative solutions play a critical role in building a sustainable future.

Selection Criteria for Heat Insulated Pipes

When choosing a heat insulated pipe, thermal performance and mechanical durability of the material should be among the priority criteria. Dec. Temperature management and longevity are the main selection factors.

When choosing high quality heat insulated pipes, the conditions of the environment to be used, as well as the energy density, should be taken into account. It is important that the chemical resistance, temperature, ease of installation and maintenance requirements are appropriate.

Finally, the compliance of the material and insulation type with sustainability standards should be evaluated in terms of long-term cost effectiveness. The reduction of environmental impacts should be targeted.

Material Quality and Properties

The material selection of heat-insulated pipes should be made taking into account various factors, as well as performance and durability.

- Polyethylene (PE): It is preferred for its flexible and corrosion-resistant structure resistant to a wide temperature range.

- Polypropylene (PP): Offers high mechanical strength and chemical resistance, robust against temperature changes.

- Steel: Provides superior performance against high pressure and temperature conditions and offers a long service life.

- Copper: It provides excellent heat conduction, stands out with its antimicrobial properties.

- Stainless Steel: It is ideal due to its corrosion resistance and robustness, as well as its hygienic use.

- Pre-insulated pipes: It increases energy efficiency by minimizing heat loss, installation is fast and practical.

Robust materials such as steel or stainless steel are recommended for pipes that will be exposed to high pressure and corrosive liquids.

Thermally insulated pipe systems, material properties should be carefully selected to ensure high tolerance and flexibility during laying.

Type Selection According to the Field of Application

The choice of heat insulated pipes should be specific to the area in which they will be used. Because each application has unique elbow and pressure needs.

Since climate control is of critical importance in greenhouses, pipes with high thermal insulation properties should be preferred. Energy efficiency is maximized in this way.

In thermal tourism facilities, materials that provide both high temperature resistance and long-term cost savings should be at the forefront. The comfort and safety of tourists should be taken into account.

For applications in residential areas, insulated pipes should be selected that meet sustainability and safety standards. In addition, this choice must be compatible with environmental and climatic conditions.

Ultimately, the balance of current and future needs, cost and performance should be taken into account when making pipe selection. Insulation quality is at the center of this balance.

Ease of Installation and Maintenance Requirements

The installation of heat-insulated pipes can be carried out quickly and effectively thanks to their modular and flexible structure. Optimized fittings simplify the installation process.

Especially in greenhouses and thermal facilities where heat-insulated pipes are used, flexible structures that will adapt to harsh terrain conditions and different climatic conditions are being sought during installation. Since these pipes are compatible with many standard mounting parts, they successfully meet the diversified installation needs and minimize the level of training and expertise required during installation, thus saving investors time and labor costs.

With low maintenance requirements, these systems promise durability and long service life. Quality thermally insulated pipes offer superior protection against rust and corrosion, which extends maintenance intervals and reduces operational costs.

As a result, the use of thermally insulated pipes increases energy efficiency and optimizes costs in the long term. To ensure this, regular inspections and periodic maintenance are important measures to prevent any leaks or loss of efficiency. High quality insulation materials and proper installation techniques increase the lifespan of piping systems and offer investors an important control mechanism over costs.

Cost Analysis and Savings Potential

Thermal insulated pipe systems may have higher costs compared to standard pipe solutions in terms of initial investment costs. However, these systems offer long-term cost advantages to investors thanks to their energy saving and reduced operational expenses. Especially in sectors where energy consumption is high, such as greenhouse installation, thermal tourism, it reveals a significant savings potential by reducing heating and cooling expenses thanks to thermal efficiency.

In a detailed cost analysis, the energy efficiency provided by using heat insulated pipes, when calculated cumulatively over the years, compensates for the initial high investment cost and increases the profit margin. This financial perspective clearly reveals the value and importance of heat insulated pipe systems for investors.

Initial Investment Comparison

It is known that thermal insulated pipe systems initially have a higher cost compared to standard pipe systems.

- Selection of pipe quality and insulation materials, has a significant impact on the cost.

- Project scale and the width of the field to be applied has the capacity to affect the total cost.

- Application and the installation processes differ in terms of labor costs.

- The budget to be allocated for maintenance and repairs it is also one of the issues that will affect the initial cost.

Considering the energy efficiency and reduced operational costs that heat insulated pipes will provide in the long term, it is possible to say that their short-term financial height will turn into an advantage.

However, it is critical for investors to determine the most appropriate investment strategy at the decision stage by evaluating the overall cost balance and long-term benefits.

Life of Insulation Materials

The material life is critical in heat-insulated pipes.

Heat insulated pipes are manufactured using high quality insulation materials. These materials must be resistant to physical impacts, chemical influences and extreme temperature changes. Durability and sustainability of the material are essential for long-term performance and energy efficiency. Their service life is guaranteed by the manufacturer under certain conditions of use.

Material life can generally vary between 20-30 years.

The quality of the insulation material is directly proportional to the correct application and maintenance. For example, damage that may occur during assembly or improper use conditions can significantly shorten the life of the material.

Therefore, in order to maximize the return on investment process, it is necessary to strictly follow the application methods and maintenance protocols recommended by the manufacturer. This sensitivity helps to avoid possible early replacement or repair costs by maintaining the functionality of insulation materials.

Observed Decrease in Bills

Heat insulated pipes reduce energy costs.

These pipe systems, which prevent heat loss, provide the highest efficiency in the transfer of hot or cold liquids depending on the quality of the insulation material. Especially in the use of geothermal energy, it is of vital importance to maintain the temperature of the water extracted from the surface and minimize thermal losses during transportation. As a result, investors encounter a low energy bill and operational efficiency increases.

Insulation materials have a reducing effect on billing costs.

While predictable energy expenditures are provided with heat-insulated pipes, more effective use of resources is encouraged. Insulation materials with high thermal resistance contribute to the long-term budget planning of enterprises by increasing the energy efficiency in the system – thanks to advanced technologies applied at the raw material and production stages.

The positive effect of energy efficiency on cost is great.

The use of modern insulation technologies reduces the total energy consumption of the system and thus maximizes the savings that can be seen in bills. Thanks to the energy efficiency regulations and incentives that come into force in 2024, consumers are paying off their investments faster and producing more at less cost through energy saving.

Application Areas of Heat Insulated Pipes

In greenhouse operations using geothermal energy sources, thermally insulated pipes are preferred to maintain constant temperature levels that support plant growth. In spa and spa applications in thermal tourism facilities, they also contribute to energy efficiency by minimizing heat loss. In addition, in process heating systems in industry and in public heating distribution networks, these pipes come to the fore, providing energy transfer with high efficiency.

Thermally insulated pipes significantly reduce costs for energy-intensive businesses. They help conserve energy and increase process efficiency, especially in energy-intensive industries such as glass, metallurgy and chemicals.

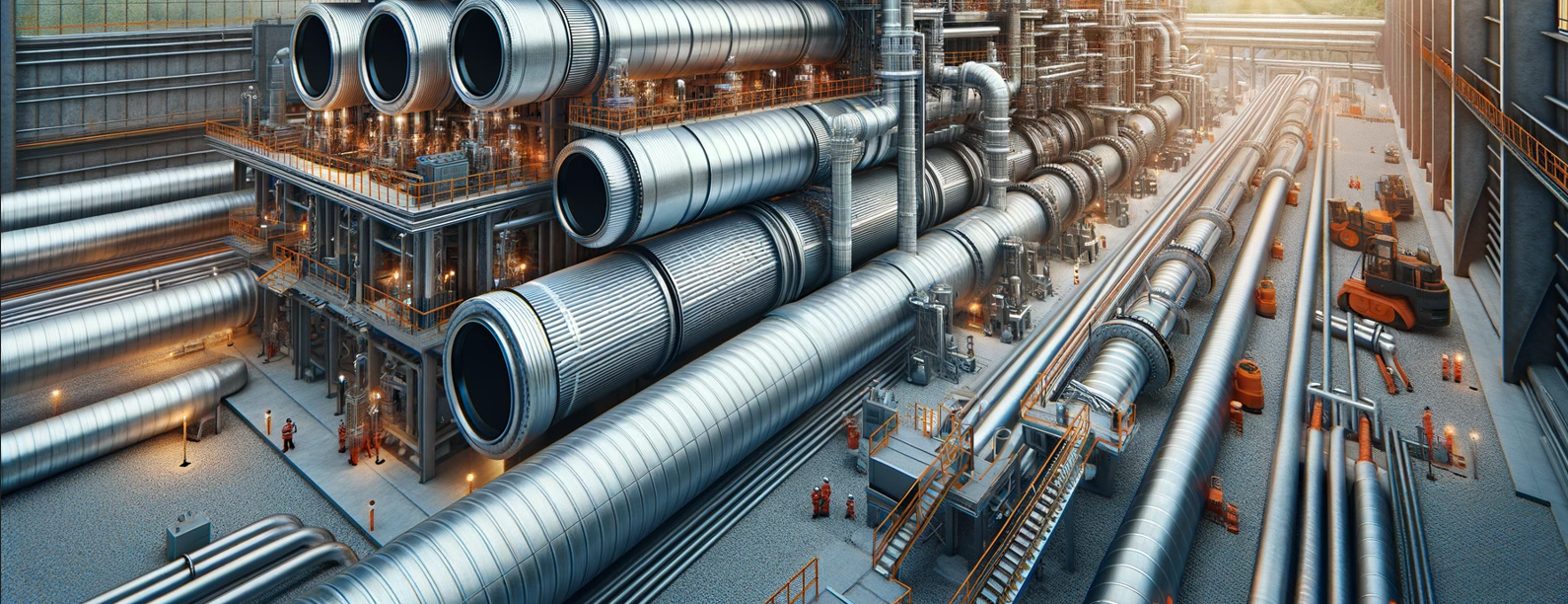

Use in Industrial Facilities

Heat insulated pipes play an important role by increasing energy efficiency in industrial processes. With the use of these pipes, while saving high energy costs, environmental emissions are also reduced.

- Low Heat Loss: It maximizes energy efficiency by minimizing heat loss in processes.

- Longevity: Manufactured from corrosion-resistant materials, it offers long-term performance.

- Process Optimization: It allows the optimization of production processes by regulating the heat flow.

- Cost Effectiveness: Thanks to the insulation, it reduces the need for reheating and therefore energy costs.

- Reducing Environmental Impacts: The reduction of energy consumption reduces the carbon footprint and supports environmental sustainability.

Pipes with thermal insulation are the key factor in reducing maintenance and operating costs.

Their widespread use in energy intensive industries makes the advantages of these materials even more important.

Optimization of Domestic Heating Systems

Thermal insulation is an application of vital importance in increasing energy efficiency in homes. You can optimize the heating system of your home by using heat insulated pipes.

While the energy transfer efficiency in heating systems increases with insulated pipes, heat losses are minimized. This increases the performance of domestic heating systems and provides less energy consumption.

The heat insulated pipes used are made of various materials (polyurethane, elastomeric foam, etc.) are produced. Since these materials have low thermal conductivity, they greatly prevent energy losses.

Thanks to the heat conservation, heating elements operating with a lower capacity can be used, which provides significant savings in operating costs. It also reduces your maintenance expenses by extending the life of your system.

In terms of energy efficiency and cost effectiveness, it is quite beneficial to prefer the use of heat-insulated pipes in your domestic heating systems.

Integration of Heating and Cooling Systems

When heating and cooling systems are taken together.

Energy efficiency and cost efficiency come to the fore with the integration of heating and cooling systems. These two systems, which complement each other, can create a perfect synchronization through heat-insulated pipes. In this context, it is critical to minimize energy losses throughout the entire system, especially for greenhouses or thermal tourism facilities connected to geothermal energy sources.

Design plays a vital role in ensuring integration.

The choice of heat insulated pipes in the design of integrated systems has a direct impact on system efficiency. A pipe of the appropriate material and thickness both increases heat transfer and reduces losses. Therefore, pipes with high insulation properties enable them to meet the heating and cooling needs of facilities at a lower energy cost.

The conversion cost also decreases for investors.

When investors integrate the right heat-insulated pipe systems, they may initially face a higher investment cost. However, investments made in this system return as cost savings in the long term with reductions in operating and maintenance expenses. considering the increase in energy costs as of 2024, such investments are becoming increasingly strategic.

Frequently Asked Questions About Heat Insulated Pipes

Do heat insulated pipes provide energy efficiency?

Yes, heat insulated pipes can reduce heat loss by between 40-60%, thus reducing energy consumption and saving costs.

What are the environmental benefits of heat insulated pipes?

These pipes reduce carbon emissions by reducing energy consumption and minimize environmental impacts, thereby helping to create a more sustainable environment.

Is the initial cost of heat insulated pipes high?

The initial investment cost of heat insulated pipes may be higher than standard pipes, but the energy savings they provide will pay for this cost in the long run.

What materials are used in the production of heat insulated pipes?

Materials such as polyethylene, polypropylene, steel, copper and stainless steel are used; these materials are resistant to high pressure, temperature and corrosion.

Is it difficult to install and maintain heat insulated pipes?

The installation of heat insulated pipes is usually easy thanks to their modular and flexible structure; low maintenance requirements also reduce operational costs.

Where are heat insulated pipes used?

They are used in greenhouses, thermal tourism facilities, industrial facilities and domestic heating systems; they are ideal for energy intensive processes.